From The Trail

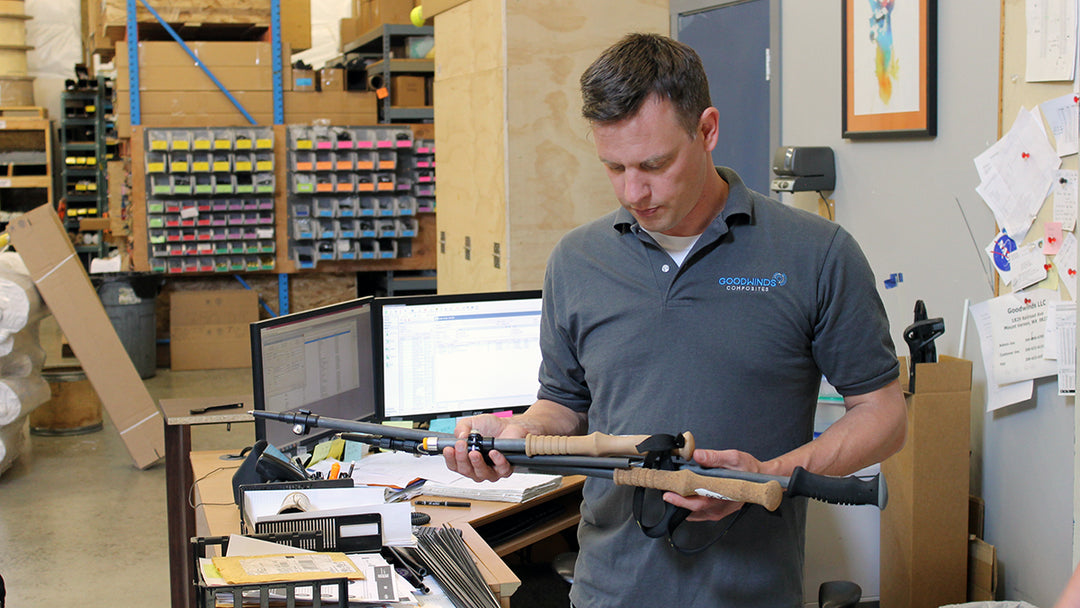

They helped NASA build a helicopter for Mars, but Goodwinds Composites is still a very down to Earth company. When we were looking for a US carbon fiber tube manufacturer for our Cnoc trekking poles, we knew we couldn't do better...

Continue reading

Our Cnoc Trekking Poles were fully funded on Kickstarter in nine hours (and a few minutes). These fully repairable trekking poles are officially happening. We're sold out of some of our early bird prices, so pledge as soon as possible to...

Continue reading

Nice landing. Is there something familiar about that helicopter? We have some really cool news about our manufacturing partner Goodwinds Composites! Along with them making our carbon fiber tubes for our new Cnoc trekking poles, they are also providing...

Continue reading

Poles are now available for purchase! When I started Cnoc Outdoors in 2016, my plan was to make the best carbon poles on the market. We began by making the Vertex poles, in the same way as everyone else—sourcing from China, where the infrastructure...

Continue reading

This past winter we had more Vertex poles out than ever before, doing things we never dreamed that they would do, including various snow sports. From skiing to hiking, cross-country to snow-shoeing, our poles were there and working hard -...

Continue reading